introduction

In the field of industrial manufacturing, standard automation equipment cannot meet the needs of enterprises for flexible production, personalized processes and complex scenarios. Non-Standard Automation takes enterprise "tailor-made" non-standard automation as its core and is becoming the key to the intelligent transformation of the manufacturing industry. This article will provide an in-depth analysis of the core advantages of non-standard automation to help you accurately grasp the technological dividends.

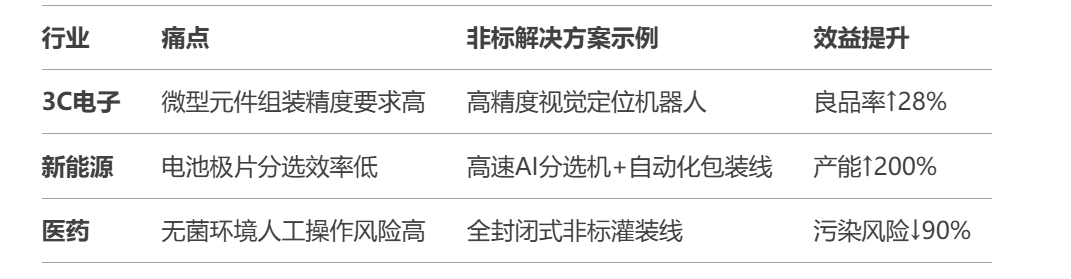

Analysis of the core advantages of non-standard automation

How can companies successfully implement non-standard automation? Clearly define needs:Sort out process bottlenecks, production capacity targets and budget ranges Choose an experienced service provider:Pay attention to industry cases, technical team composition, and after-sales response capabilities.Phased implementation:It is recommended to gradually expand from single station transformation to full line automation

How can companies successfully implement non-standard automation? Clearly define needs:Sort out process bottlenecks, production capacity targets and budget ranges Choose an experienced service provider:Pay attention to industry cases, technical team composition, and after-sales response capabilities.Phased implementation:It is recommended to gradually expand from single station transformation to full line automation